|

Attribute |

Value |

|

Brand / Manufacturer |

PowerSyntax |

|

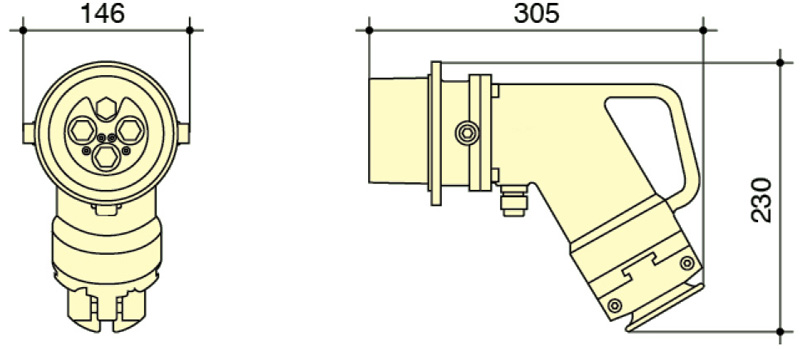

Manufacturer Part Number |

MB250A-BS-B |

|

Plug / Socket |

Female Plug (Mobile Angled Type) |

|

Mounting Type |

Cable Mount |

|

Pole Format |

4P = 3P+E |

|

Current Rating (Ampere) |

250A |

|

Voltage Rating |

380V ~ 415V (customized up to 1000 V) |

|

Protection Grade of IP Rating |

IP67 |

|

Protection Grade of Shock Resistance |

IK10 |

|

Ambient Temperature |

- 40 ℃ to + 100 ℃ |

|

Insulation Resistance (Phase-phase and phase-earth) |

> 500 MOhm |

|

Comparative Tracking Index of the Insert |

> 600 CTI |

|

Cable CSA (Cross-sectional Area) for L1, L2, L3 Rigid Conductor EN 60228 Class 1+2 |

☐ 70 mm2 ☐ 95 mm2 ☐ 120 mm2 ☐ 150 mm2 |

|

Cable CSA (Cross-sectional Area) for Earthing Rigid Conductor EN 60228 Class 1+2 |

☐ 70 mm2 ☐ 95 mm2 ☐ 120 mm2 ☐ 150 mm2 |

|

Pilot Cable CSA (Cross-sectional Area) Conductor EN 60228 Class 1+2 |

1.5 - 4.0 mm2 |

|

Diameter of Cable Gland for Cable |

45 - 66 mm |

|

Clock Position |

6 h |

|

Frequency (Hertz) |

50-60 Hz |

|

Gender |

Female |

|

Body Orientation |

Angled |

|

Connection Technology |

Ferrule Crimp Terminal (optional sizes as above) |

|

Material of Plastic Housing |

Full Body Cast Aluminum |

|

Material of Metal Contacts |

Silver Plated Brass |

|

International Standard |

IEC 309-5, EN 60309-5, GB/T 11918.5 |

|

Other voltages and frequencies available on request. |

|

PowerSyntax has established itself as a world leader in the design and manufacturing of safety-interlocks, including ship-to-shore power connection solutions. Our team works with customers worldwide to build custom engineered solutions for both military and commercial applications.

Increases in maritime shipping and environmental pollution concerns have created a demand for ship-to-shore power solutions that comply with environmental restrictions in ports and harbors. Cold-ironing, a process of ships shutting down on-board generation and then plugging into shore-side power while in berth, can greatly reduce air pollution in neighboring areas.

According to some estimates, cold ironing removes more than three tons of nitrogen oxides (NOx) and 350 pounds of particulate matter from the air in large metropolitan areas. The US Military has used this method for many decades to reduce on-board manpower requirements while in port.

With a continuous commitment to Safety, Innovation, Value, and Customer Service, PowerSyntax forges the way in ship-to-shore power connection technology.

PowerSyntax shore power plugs and sockets have GB/T 11918.5 qualification approval and comply with IEC 60309-5. PowerSyntax builds the most durable high current plugs and sockets on the market; we make the full body of the shore power high current plugs and sockets by electropolished castings aluminium. This reduces corrosion and increases longevity in harsh marine environments under extreme and demanding use.

PowerSyntax Shore power plugs can be supplied factory-potted with customer-specified cable types in lengths up to 1000’. The plug or individual plug components can also be furnished for on-site assembly or repair.

PowerSyntax provides world-wide support to customers who need mating and disconnect capabilities for the shore-power capable vessels. Our commitment to high inventory levels and a responsive production team ensures quick delivery in order to support customer critical needs.

• Navy Ships & Bases

• Barges

• Yachts & Marinas

• Container Ships & Ports

• Cruise Ship Terminals

The connectors are designed for ambient temperatures from - 40 ℃ to + 100 ℃. This ensures full functionality at low and very high temperatures. This leads to significantly fewer plant failures (reduced risk of overheating) and reduced fire risk. Another important aspect for vaious industries, such as tunnel construction, construction sites, mines is the high robustness of the connectors. These can withstand loads of up to 2 tonnes.

The IK code is a coding system according to IEC/EN 50102 or IEC/EN 62262, which indicates the degree of protection by a housing against harmful external stresses. Each characteristic number of the IK code represent a stress relief value.

If standard solutions do not meet all the requirements of an application, customer-specific solutions are made upon the request.

This article will help you identify the various types of high current plugs and sockets, both mobile and fixed.

How to identify the compatible version of high current plugs and sockets

The IP rating system provides a means of classifying the degree s of protection from dust, water and impact afforded by electrical equipment and enclosures.

We started our manufacturing of Portable Distribution Box, with experienced technical engineers team and top sales team.

Click for WhatsApp

Get a Quote