|

Attribute |

Value |

|

Brand / Manufacturer |

PowerSyntax |

|

Manufacturer Part Number |

75251 |

|

Plug / Socket |

Plug (Wall Mounted Type) |

|

Mounting Type |

Wall Mount |

|

Pole Format |

4P = 3P+E |

|

Current Rating (Ampere) |

200A |

|

Voltage Rating |

380V ~ 415V (customized up to 1000 V) |

|

Protection Grade of IP Rating |

IP67 |

|

Protection Grade of Shock Resistance |

IK10 |

|

Ambient Temperature |

- 40 ℃ to + 100 ℃ |

|

Insulation Resistance (Phase-phase and phase-earth) |

> 500 MOhm |

|

Comparative Tracking Index of the Insert |

> 600 CTI |

|

Cable CSA (Cross-sectional Area) Rigid Conductor EN 60228 Class 1+2 |

70 - 150 mm2 |

|

Pilot Cable CSA (Cross-sectional Area) Conductor EN 60228 Class 1+2 |

1.5 - 4.0 mm2 |

|

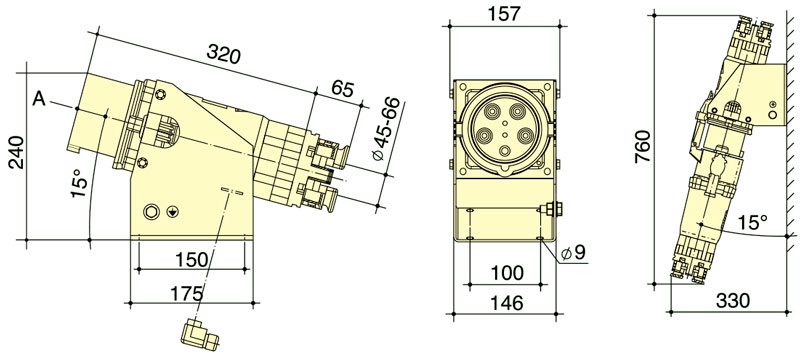

Diameter of Cable Gland for Cable |

45 - 66 mm |

|

Clock Position |

6 h |

|

Frequency (Hertz) |

50-60 Hz |

|

Gender |

Male |

|

Body Orientation |

Straight |

|

Connection Technology |

Screw Terminal |

|

Material of Plastic Housing |

Cast Aluminum |

|

Material of Metal Contacts |

Silver Plated Brass |

|

International Standard |

IEC 309-2, EN 60309-2, DIN VDE 0623 part 1 |

|

Other voltages and frequencies available on request. |

|

|

Current |

Poles |

230V 50a.60Hz |

400V 50a.60Hz |

500V 50a.60Hz |

690V 50a.60Hz |

1000V 50a.60Hz |

|

4P 5P 9h 9h |

4P 5P 6h 6h |

4P 5P 7h 7h |

4P 5P 5h 5h |

4P 5P 1h 1h |

||

|

160A |

4P |

75250X |

75251X |

75252X |

75253X |

75254X |

|

5P |

75255X |

75256X |

75257X |

75258X |

75259X |

|

|

200A |

4P |

75250 |

75251 |

75252 |

75253 |

75254 |

|

5P |

75255 |

75256 |

75257 |

75258 |

75259 |

For many years, PowerSyntax has been a strong partner in the area of CEE plugs and socket devices up to 125 A. Now the well-known program has been extended to high-current plug and socket devices up to 400 A. As usual, highest priority is given to safety standards, quality and reliability. These plug and socket devices can be found in a variety of applications such as tunneling, shipbuilding, opencast mining or the mining industry, where they fully meet the customers‘ requirements.

The heavy duty range supplements the plugs and sockets currently covered by EN 60309-2, making available rated currents of 160A, 200A, 250A and 400A and rated voltages of up to 1000 V. The design is based on the following standards: IEC 309-1, EN 60309-1, DIN VDE 0623, part 1.

In applications where high current connectors are used, the safety, quality and reliability are the top priorities for customers. In order to fulfill this task, all these properties were bundled into one product range. Thus, all customers receive a product with the highest degree of performance.

Whether in tunnel construction, where extremely mechanical strength is required or railway applications where vibration-proof is of highest importance, the high current connectors are always the right choice.

Silver plated contacts with a maximum contact surface and thus minimal power loss contribute to the reduction of energy costs. They also ensure high reliability in different environmental conditions, such as strong vibrations, high temperatures, heavy soiling, etc ... When worn, the contacts can be easily and quickly replaced using standard tools.

The connectors are designed for ambient temperatures from - 40 ℃ to + 100 ℃. This ensures full functionality at low and very high temperatures. This leads to significantly fewer plant failures (reduced risk of overheating) and reduced fire risk. Another important aspect for vaious industries, such as tunnel construction, construction sites, mines is the high robustness of the connectors. These can withstand loads of up to 2 tonnes.

The IK code is a coding system according to IEC/EN 50102 or IEC/EN 62262, which indicates the degree of protection by a housing against harmful external stresses. Each characteristic number of the IK code represent a stress relief value.

Each socket is equipped with a finger touch protection in order to safeguard the user against electrical shocks in the event of unintentional contact with live parts.

The connectors are IP67. They are dust-proof and suitable for temporary immersions under water. The connector units (high current metal socket boxes) are IP55, which means protected against dust and splashing water.

Connectors for every task

If standard solutions do not meet all the requirements of an application, customer-specific solutions are made upon the request.

This article will help you identify the various types of high current plugs and sockets, both mobile and fixed.

How to identify the compatible version of high current plugs and sockets

The IP rating system provides a means of classifying the degree s of protection from dust, water and impact afforded by electrical equipment and enclosures.

We started our manufacturing of Portable Distribution Box, with experienced technical engineers team and top sales team.

Click for WhatsApp

Get a Quote